Investigation of Interior Corrosion of

Above-Ground Storage Tanks

Senior Prinicipal Engineer

The Failure Analysis and Welding (FAW) group at Kiefner traditionally investigates the causes of failures of buried pipelines carrying various petroleum products ranging from crude oil, refined liquid products, natural gas, and condensates. However, many of our customers do not know that Kiefner has the expertise to investigate failures, not only of other types of oil and gas equipment such as valves, fittings, pumps, and tubing but also equipment completely unrelated to the oil and gas industry. Recent examples include conducting failure analyses of aluminum sheets used in heat exchangers, metal coatings used in garbage disposers, and stainless-steel containers used in food refrigeration systems. This blog, which is expected to be part of a series of blogs, will focus on a recent investigation of premature corrosion inside an above-ground storage tank.

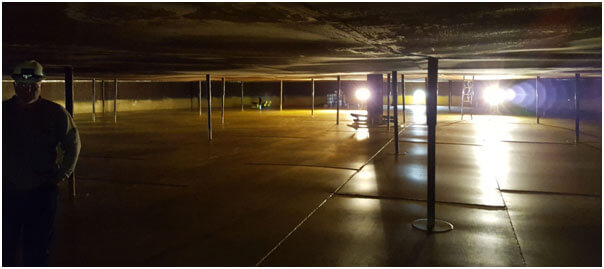

The tank was filled with over 4 million gallons of water, and while the actual hydro testing of the tank required only a 24-hour hold of the water to check for leaks (none were detected), filling and emptying the tank took 23 days. During this time, uncoated carbon steel was exposed to potable water taken directly from a nearby fire hydrant. After the tank was emptied and allowed to dry for a couple of days, the interior surfaces of the tank were visually examined by entering the tank (Figure 2). The tank was found to be coated with an unexpectedly high concentration of rust deposits.

The bottom of the tubercle acts as the anode, while the uncorroded metal surface outside the mounds serves as the cathode in an electrochemical cell. These tubercles are also often associated with microbiologically induced corrosion (MIC). MIC is often seen on buried pipelines’ exterior surfaces because of the surrounding soil’s bacteria-rich environment. However, MIC can also be present in locations not generally associated with bacteria. A sensitive technique for identifying the DNA of bacteria in a sample called quantitative polymerase chain reaction (qPCR) was used to identify several types of bacteria and the amount present in the collected corrosion products. It was also used to determine which percentage of the bacteria were alive and dead. Subsequent analysis of the collected corrosion products from the same tank after two months of continuing to dry out the interior revealed that almost all the bacteria had died. An analysis of the testing procedure revealed that the practice of aerating the incoming water to remove chlorine from the water had a deleterious effect on causing the observed rust and promoting MIC growth.