ILI Correlation using CorroSure

Calculating Corrosion Growth Rates Using Consecutive ILI Results

In-Line Inspections (ILI) are commonly implemented for the continued integrity management of pipelines, particularly in response to the ongoing threat of corrosion. The corrosion growth rate (CGR) plays an essential role in the optimization of re-inspection intervals. Our method of obtaining the CGR uses successive ILI runs and performs a feature-to-feature comparison.

Unmatched Precision through Pattern-Matching

CorroSure helps you achieve unparalleled accuracy for your ILI data set correlation projects. Using advanced algorithms, CorroSure pattern-matches data from successive in-line inspections. Any technology can be correlated, and any vendor can be evaluated. This process ensures high confidence in the matched data, leading to exceptionally accurate results. We understand the critical nature of precise data in pipeline management, and CorroSure is engineered to deliver just that.

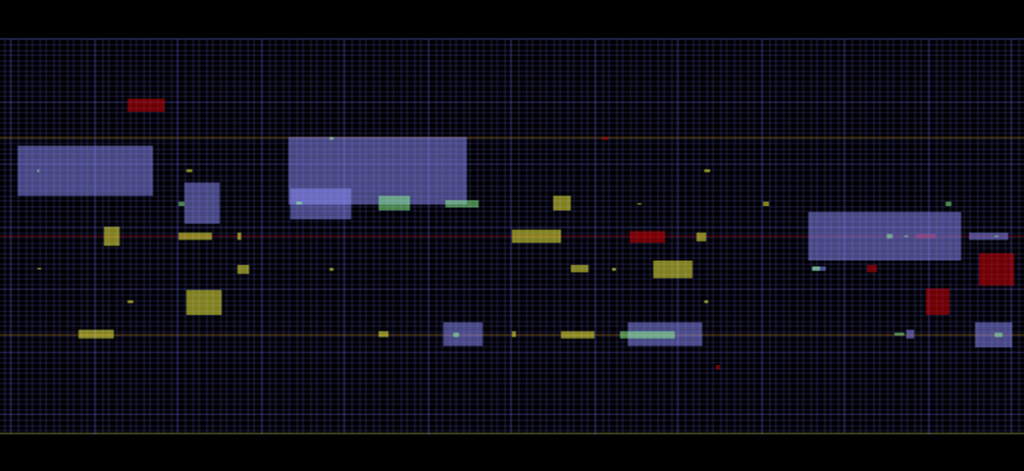

Below is an example of data from two successive years in CorroSure. The first-year data is represented by the green ovals, and the second-year data is represented by the yellow rectangles. The image of overlaid data demonstrates where growth is predicted.

Understanding the Results

Matched data pairs are evaluated, comparing metal loss depths of two successive inspections. A unity graph quickly shows corrosion growth in a meaningful yet familiar way. Negative bias could be due to corrosion growth, which is analyzed further to provide a calculated GCR specific to the pipeline. Any metal gain could indicate ILI measurement error or mill features, which should not be subject to time-dependent growth (corrosion). Areas, where recoats or other repairs have occurred, should be considered separately from the overall CGR. Kiefner provides the experience and insight to help you understand your data.

Benefits of CorroSure

- Align and match ILI-reported indications — CorroSure aligns and matches In-line Inspection (ILI) reported indications with visual, pattern-matching detail. Advanced algorithms and highly experienced data analysts thoroughly review the data to ensure comprehensive data accuracy.

- Full pipeline system correlated — CorroSure correlates the entire pipeline system, providing a holistic view of your infrastructure. No segment is left unexamined, ensuring a comprehensive understanding of your pipeline’s health.

- Indicate corrosion growth areas — CorroSure pinpoints areas of corrosion growth with exceptional accuracy. Identifying these vulnerable spots empowers proactive maintenance and timely interventions, minimizing risks.

- Correlate differing technologies or vendors — CorroSure allows you to compare data from different technologies, such as MFL and UT. Additionally, it enables the comparison of ILI data from various vendors. This comparative analysis aids in selecting the most effective solutions for your specific needs.

- Calculate bias and corrosion growth rates — CorroSure calculates bias and corrosion growth rates with advanced algorithms. These precise calculations offer insights into trends, enabling data-driven predictions and strategic planning.

- Charts demonstrating error distributions — CorroSure presents data results in intuitive charts that effectively illustrate error distributions. These visual insights simplify complex data, allowing for quick and informed decision-making.

Kiefner’s Customized Approach

Kiefner analyzes diverse ILI datasets to prioritize anomaly responses. We craft tailored mitigation strategies, ensuring pipeline safety against unforeseen anomalies. With tools like CorroSure, Kiefner ensures optimal pipeline function and heightened safety standards. For more information on using CorroSure in your next project, contact us at [email protected].