Materials Testing

The Significance of Materials Testing

Understanding material properties is pivotal in designing and operating equipment. A myriad of non-destructive and destructive testing methods exists, furnishing data to ascertain product manufacture consistency, and performance levels. Effective materials testing empowers clients to gauge service suitability or pinpoint system concerns.

Kiefner's Expertise in Material Testing

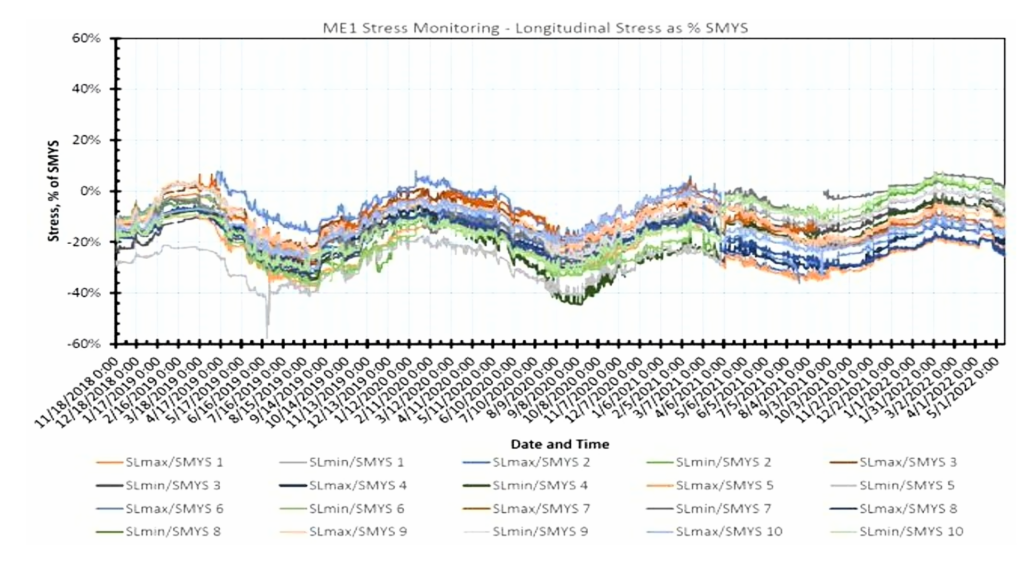

With a rich history in both non-destructive and destructive material testing, Kiefner provides clients with the insights necessary for comprehensive system and component assessment. Our aim is to deliver material and component data, aiding operators in minimizing system disturbances throughout the asset’s lifespan. Using advanced data-management software, we record, report, and trend data, enabling predictive modeling and asset life estimation.

Universal Importance of Materials Testing

Robust materials testing and inspection programs benefit every industry. Whether verifying material characteristics, confirming functional properties, or probing defects, our testing ensures optimal function, quality, and asset safety.

Benefits of Partnering with Kiefner

-

- Comprehensive understanding of material mechanical properties.

- Assured system integrity evaluation.

- Verification of construction materials.

- Early identification of potential concerns.

- Validation of expected exposure models through destructive testing.

- Enhancement in product quality.

- Uplifted safety for personnel in potential energy release zones.

Kiefner's Lab in Columbus, Ohio

Our Columbus-based laboratory is a hub for diverse testing, including:

-

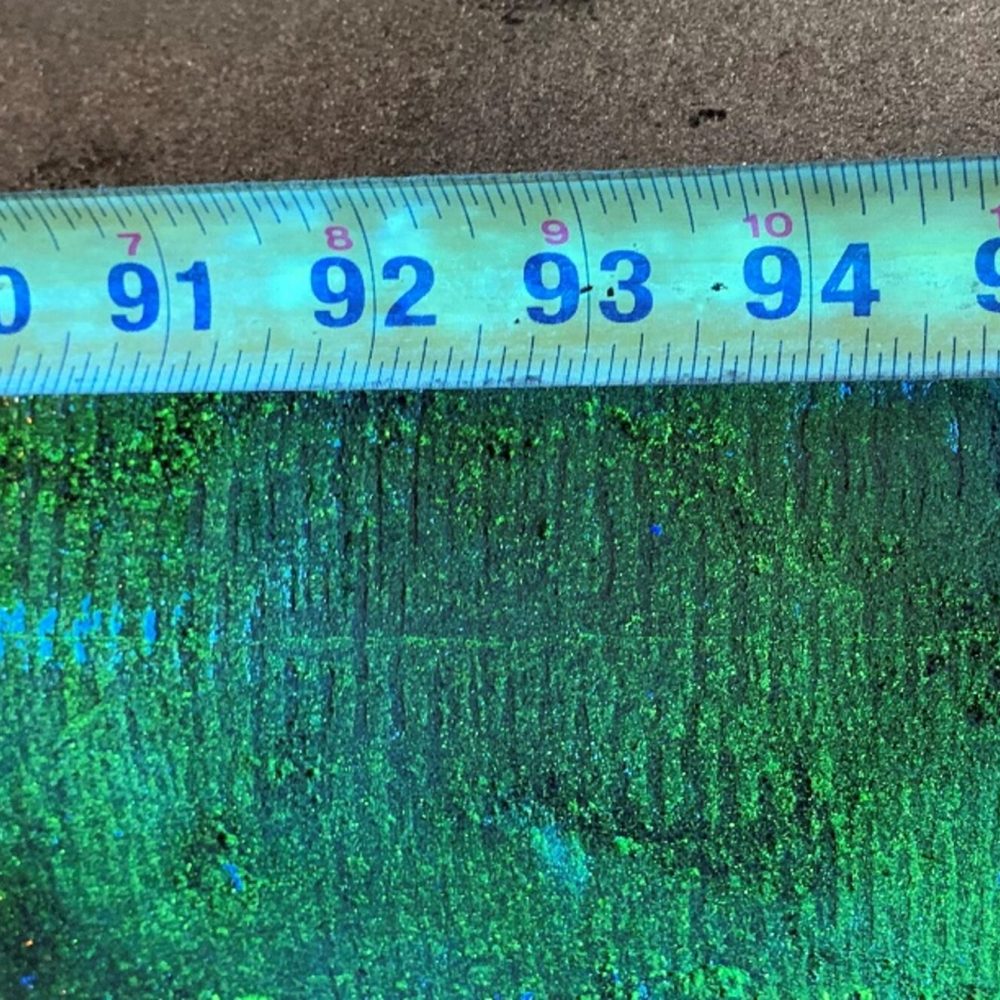

- Failure Investigations: This covers comprehensive metallurgical studies of pipeline-related failures such as fractography, metallography, non-destructive examination, material characterization, deposit and material chemistry, fatigue crack propagation, weld evaluation, and linear polarization resistance.

- Instrumented Burst Tests: Capabilities include standard endcap testing and variable axial loading testing.

- Instrumentation: Incorporating strain gauges, multi-channel data acquisition, Labview programming, and tools to measure displacement, pressure, temperature, and acceleration.

For our existing clientele, samples can be directly sent to our laboratory after completing the necessary forms, ensuring a smooth and efficient testing process.

Trust Kiefner for unparalleled precision and insights in materials testing. With us, you can secure your assets and enhance operational efficiency.