Destructive Testing and Material Verification

The Essence of Material Testing

When engineers design equipment and structures, they define the essential physical properties of the construction materials. Destructive testing is pivotal in material verification, ensuring alignment with the engineer’s design specifications, and compliance with regulatory standards. Whether during initial manufactures, such as pipe mill inspections or during structural welding tests post-fabrication, material verification remains crucial.

Services & Capabilities

Kiefner operates accredited materials testing labs, upholding CSA, NADCAP, & ISO standards. Our offerings include:

- Uniaxial tensile-strength testing with computerized stress-strain plots,

- Charpy impact tests (CVN),

- Macro and micro testing (encompassing Vickers, Brinell, and Rockwell hardness tests),

- Macro etching,

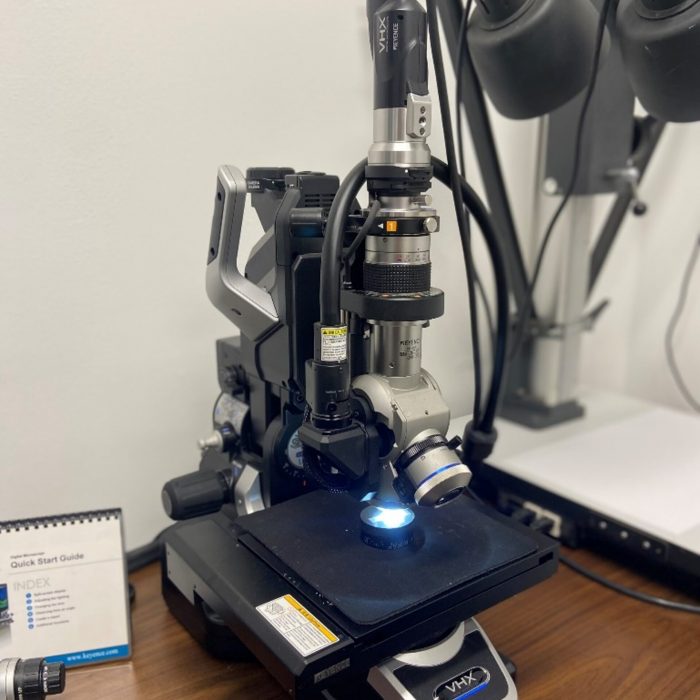

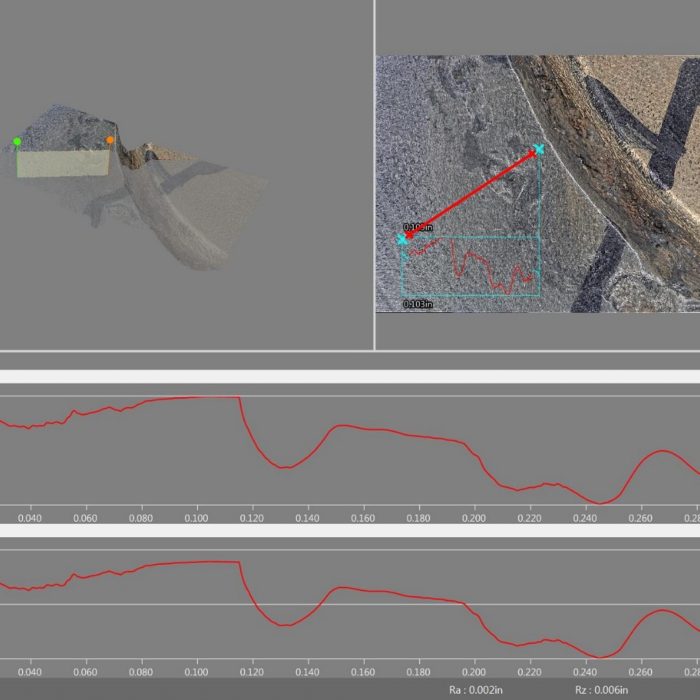

- Comprehensive metallurgical services & microscopy, and

- Bend testing.

Our adept lab technicians collaborate with our material and welding engineers and NDT technicians, ensuring a seamless and integrated NDT service. Our state-of-the-art labs are furnished with equipment verified and calibrated to industry standards.

When is Material Testing Essential?

Material testing is essential:

-

- At the outset of a new project.

- For materials verification, welding procedure specification, and welder qualification.

- During retrofitting, repairs, or when positive material identification is necessary.

- When defects are identified during non-destructive testing.

- During FMEA risk assessments and maintenance, to comprehend how material properties might have evolved.

Why Kiefner's Services Stand Out

Our services stand out due to:

-

- Rapid response and turnaround times.

- Expert technicians equipped with cutting-edge material testing tools.

- A robust network of materials testing laboratories.

- Synergized services integrating NDT inspection and engineering departments.

Kiefner's Lab in Columbus, Ohio

Our Columbus-based lab is primed for extensive testing, from failure investigations, instrumented burst tests, and corrosion tests to standard mechanical properties tests. Our exhaustive failure investigations cover areas from fractography, metallography, non-destructive examination to fatigue crack propagation, weld evaluation, and more.

Instrumented Burst Tests capabilities include standard endcap testing and variable axial loading testing. We employ various instrumentation, such as strain gauges, multi-channel data acquisition, Labview programming, and more.

Existing Kiefner clients can directly send their samples to our laboratory after completing the necessary forms.

Choose Kiefner for a comprehensive, precise, and efficient material testing experience. Let’s safeguard your assets and ensure their longevity together.