Engineering Critical Assessment (ECA): Comprehensive Analysis for Safe Pipeline Operations

Introduction to ECA

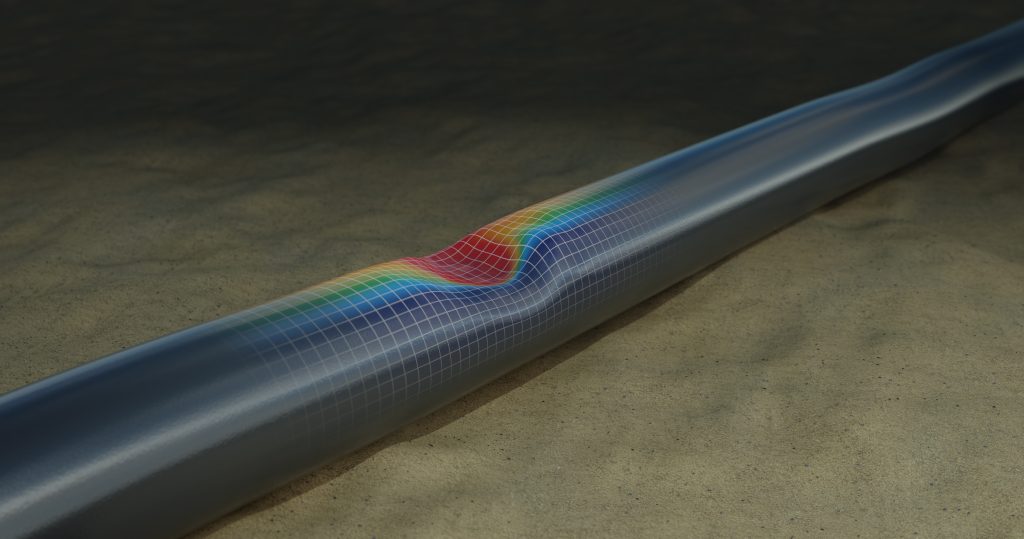

Engineering Critical Assessment (ECA) is a nuanced methodology focused on determining the service fitness of a defect or anomaly using fracture mechanics principles. This approach, critical for pipeline design, construction, and operation, hinges on three key elements: material property, flaw specifics, and applied stress. ECA plays a pivotal role in guiding maintenance, inspection prioritization, and ensuring the longevity of pipeline systems.

Core Features of ECA

Kiefner addresses many unique anomaly scenarios, including the following:

- Flaw Acceptance and Analysis: This process determines the maximum tolerable flaw size for specific materials across various construction and operating conditions.

- Applicable Standards: Kiefner conducts ECA analyses in line with globally recognized standards, such as API 1104, API 579, CSA Z662, and BS 7910.

- Broad Range of Failure Mechanisms: Our analysis comprehensively addresses mechanisms including brittle fracture, ductile instability, plastic collapse, and fatigue growth.

Specialized ECA Services by Kiefner

-

-

- Calculation of welding defect acceptance criteria as per API 1104 Annex A.

- Comprehensive ductile tearing assessments.

- Detailed interpretation of J-R test results.

-

Advantages and Applications of ECA

-

-

- Strategic Planning: Assists in determining welding procedures and inspection techniques during an installation’s design phase.

- Defect Management: Evaluates known defects deemed unacceptable by the fabrication code.

- Failure Analysis: Pinpoints any failure to achieve the toughness stipulations of a fabrication code.

- In-Service Flaw Decisions: Assess in-service flaws for decisions on their disposition, including potential repairs or safe retention.

-

The Kiefner Advantage

ECA demands a collaborative approach from a multi-disciplinary team. At Kiefner, our specialists possess deep expertise in the three fundamental ECA parameters: stress analysis, flaw characteristics, and material property assessment.

We’ve applied our ECA expertise across varied scenarios, including:

-

-

- Fatigue-sensitive structures like dynamic and steel catenary risers and

- Time-critical onshore and offshore pipeline projects that employ high-productivity welding processes and advanced ultrasonic testing for weld quality.

-

Our commitment is to deliver thorough stress-analysis consultation, ensuring clients have vital insights about their pipeline integrity where it’s most crucial.