ILI Comparison Tools for Enhanced Pipeline Integrity

Harnessing ILI's Potential

In-line Inspection (ILI) is vital for maintaining pipeline safety and integrity. As ILI technologies advance, Kiefner has adopted cutting-edge software for deeper data analysis and accurate evaluations.

LaserSure™: Precision Meets Technology

The correlation of MFL-based ILI predictions with locations of actual metal loss can be complicated when a high concentration of metal loss features is present or complex shapes of metal loss are encountered. Both are known to introduce locating and sizing errors due to the physics of magnetic flux leakage. As a result, distance-based correlation may prevent the determination of true ILI performance. The patented LaserSure™ process was developed to employ pattern matching, aligning ILI features with the actual metal loss measured from a laser to improve the accuracy and reliability of correlations.

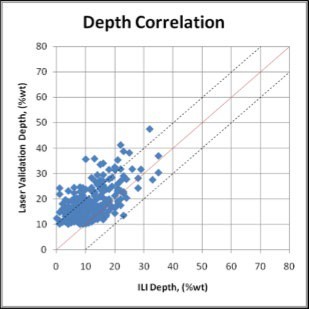

LaserSure™ can efficiently match a large number of individual boxes and clusters to obtain depth and burst pressure correlated data. Extracting the data from LaserSureTM allows for the creation of unity charts, which can indicate the presence of a depth bias in the ILI depending on the average results. The data for the graph below shows the mean for the depth error population to be -6.2%wt, indicating a tendency for the ILI to undercall actual depths. If errors are normally distributed, they are assumed to be measurement errors. However, a calibration for the ILI data can be determined if the data demonstrates a bias, as in the example provided.

LasureSure™: Pattern Matching Technique

The 2013 ILI Systems Qualification Standard API 1163 The LaserSure™ software evaluates raw laser data to determine and record the two-dimensional metal loss (axial and circumferential) to a specified wall thickness threshold boundary. It also tests in-ditch verifications to determine ILI tool performance. However, not all ILI assessments warrant excavations. The API 1163 Second Edition outlines methods to make decisions using alternative data sources.

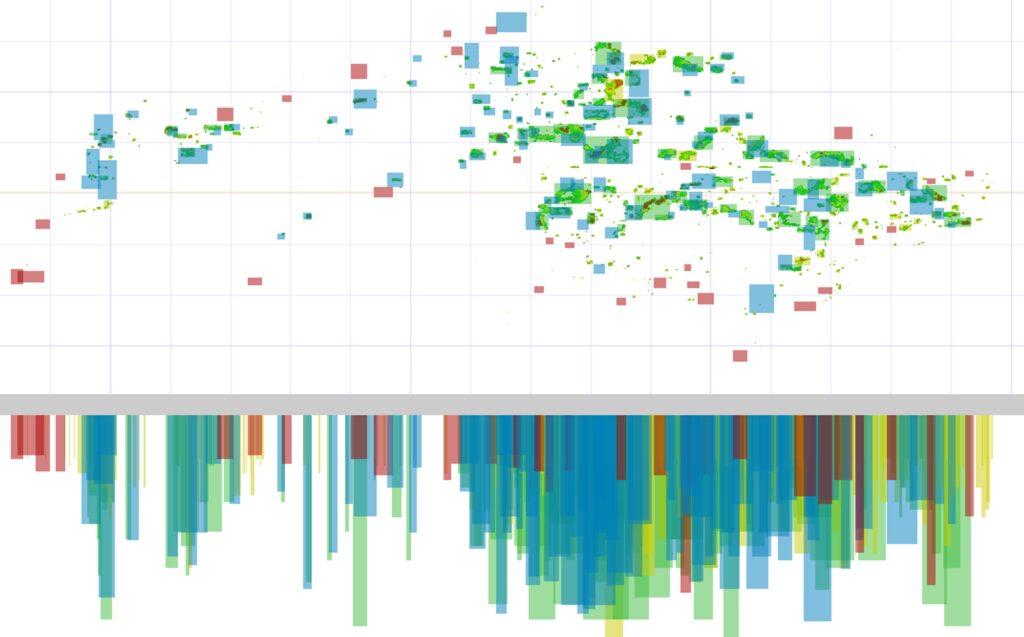

ILI features (positions, depths, lengths, and widths) are also imported into the LaserSure™ software. Patterns are overlaid and spatially matched. The example provided visually represents an overlay of the ILI data with the laser data.

Kiefner's Customized Approach

Kiefner analyzes diverse ILI datasets to prioritize anomaly responses. We craft tailored mitigation strategies, ensuring pipeline safety against unforeseen anomalies. With tools like LaserSure™, Kiefner ensures optimal pipeline function and heightened safety standards.

For more information on using LaserSure™ for your next project, contact us at [email protected].