ILI Data Interpretation: Enhancing Pipeline Safety Through Informed Decision Making

The Significance of ILI Interpretation

Interpreting In-line Inspection (ILI) results is essential for determining the right course of action. Proper analysis helps prioritize interventions and resources, ensuring anomalies, especially those in challenging locations, are addressed appropriately.

Key Anomaly Scenarios Addressed by Kiefner

- Denting and Metal Loss: Corrosion within a dent usually presents less concern than similar corrosion on plain pipe. However, gouge-induced metal loss often poses a significant risk.

- Seam Corrosion: It’s vital for ILI tools to distinguish between crack-like selective seam weld corrosion (SSWC) and regular corrosion affecting a low-frequency ERW seam.

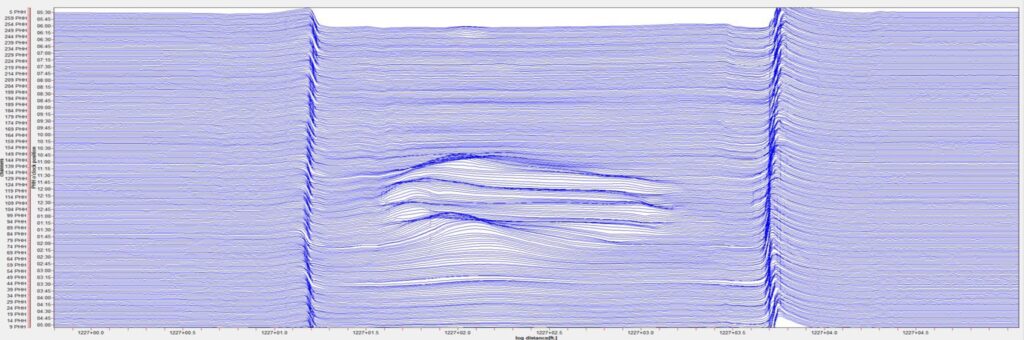

- Wide Area Corrosion: In extensive corrosion areas, not all pits might be detected or sized accurately by ILI tools. Ignoring such defects might lead to an underestimation of the structural risk when evaluating the pipe’s remaining strength.

Kiefner's Approach to ILI Data Interpretation

At Kiefner, we’re focused on refining ILI signal interpretation techniques. Our primary objective is to bolster pipeline safety by effectively identifying potential integrity threats and efficiently addressing non-critical anomalies.

Our continuous efforts aim to provide pipeline operators with the most accurate information, ensuring the longevity and safety of pipeline systems.