Remaining Life Assessment of Hydrogen Pipelines for Flaw Sizes Below ILI and NDE Detection Limits

Kiefner and Associates, Inc., Houston, USA. Kiefner and Associates, Inc., Columbus, USA.

While pressure cycle fatigue may not typically be a significant concern in conventional gas pipelines, introducing hydrogen changes the dynamic. This makes pressure cycle fatigue analysis a critical factor in ensuring mechanical integrity. Hydrogen can significantly alter material properties through embrittlement, accelerating crack growth rates. As the industry shifts towards hydrogen blending in natural gas pipelines, accurate remaining life assessments become essential for effective integrity management. this is especially true for small flaw sizes that may not be detectable by ILI or other NDE tools.

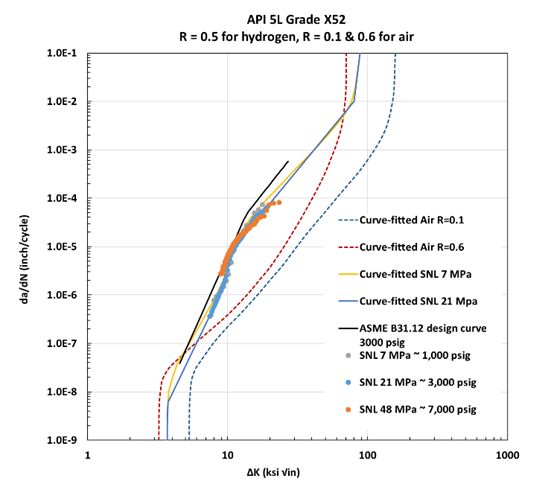

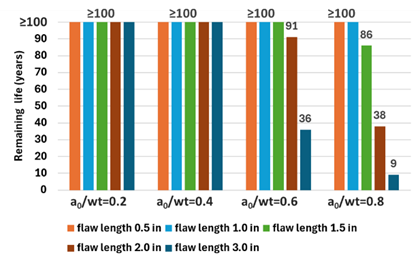

As part of ongoing research for the United States Department of Transportation (USDOT) Pipeline and Hazardous Materials Safety Administration (PHMSA), this paper addresses the challenge of assessing flaws just below the detection limits of ILI and NDE tools. Through a series of case studies, the remaining life of these subcritical flaws is estimated, considering variables such as flaw size, location (e.g., pipe body, seam weld), pipeline grade, and the severity of pressure cycles. Unlike the traditional Paris law approach, commonly used for Region II (stable crack growth) fatigue analysis, this study employs advanced models to capture a broader range of material behaviors, including Region I (threshold) and Region II (rapid crack growth), while also accounting for pressure cycle severities. Experimental data is directly incorporated into fatigue crack growth calculations to further reduce conservatism instead of relying on standard fatigue design curves.

Operators will gain insights into how hydrogen exposure impacts pipeline remaining life and can use this knowledge to make informed decisions for setting reinspection intervals and extending the operational life of pipelines in hydrogen environments. While the findings provide important guidance, they also emphasize the need for ongoing research and thorough technical assessments.