Fatigue and Fracture Mechanics

Pipeline Safety Amidst Defects

Pipelines can operate safely even with corrosion defects and cracks. Operators must distinguish between safe defects and those necessitating repair. We employ fundamental, regulatory-approved methods to determine the remaining strength of pipes affected by corrosion and cracking.

Understanding Fatigue Failure

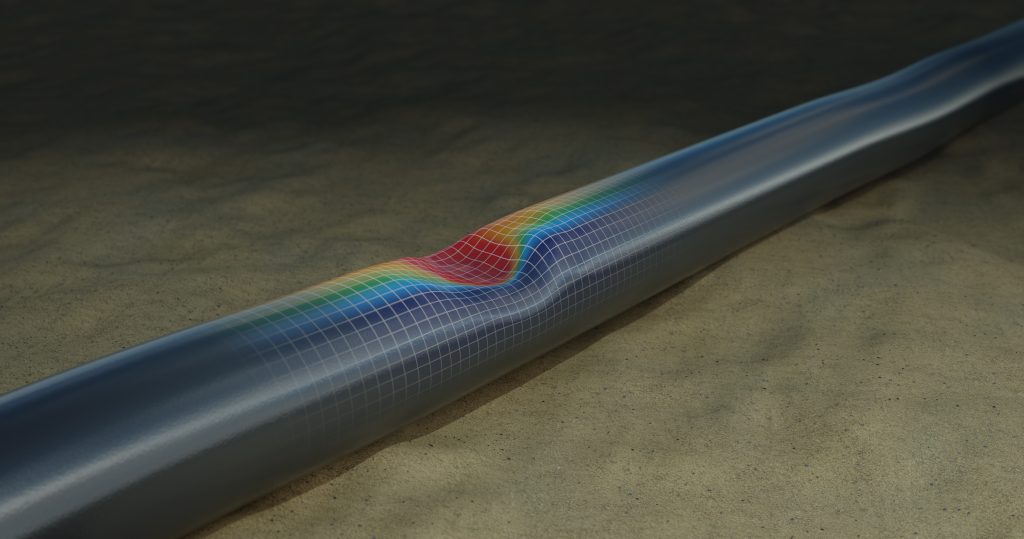

Fatigue failure arises when a material experiences cyclic loading, meaning it undergoes repeated loading and unloading.

The Importance of Re-Examination

For in-service pipelines, implementing a rigorous re-examination schedule is paramount. Pressure cycles can exacerbate fatigue cracks, stress corrosion cracks, and other detrimental conditions, potentially leading to a pipeline’s failure.

Our Expertise at Kiefner

Our team can accurately assess your pipeline’s remaining lifetime and potential failure pressure. We employ advanced mathematical models, combining our comprehensive understanding of pipeline system materials, design, and operation with our evaluations grounded in established fracture mechanics principles and cutting-edge calculation methods.

Valuable Deliverables for Operators

With our expert analysis, operators can benefit from:

-

- Benchmark Comparisons: We compare your pressure cycle spectrum to benchmark cycles in our extensive library, which is essential for determining the failure probability due to fatigue crack growth.

- Re-Assessment Intervals: We provide recommended practical intervals to periodically check the defect using hydrostatic testing or ILI/NDE tools.

Moreover, we offer our state-of-the-art software for purchase, allowing you to conduct fatigue-life calculations. Training sessions for effective software utilization are also available.

Elevated Confidence in Pipeline Integrity

Pipeline operators collaborating with Kiefner for fitness-for-service evaluations can expect bolstered confidence in the robustness of their pipeline integrity management programs.