ILI Qualification:

Enhancing Pipeline Safety and Data Integrity

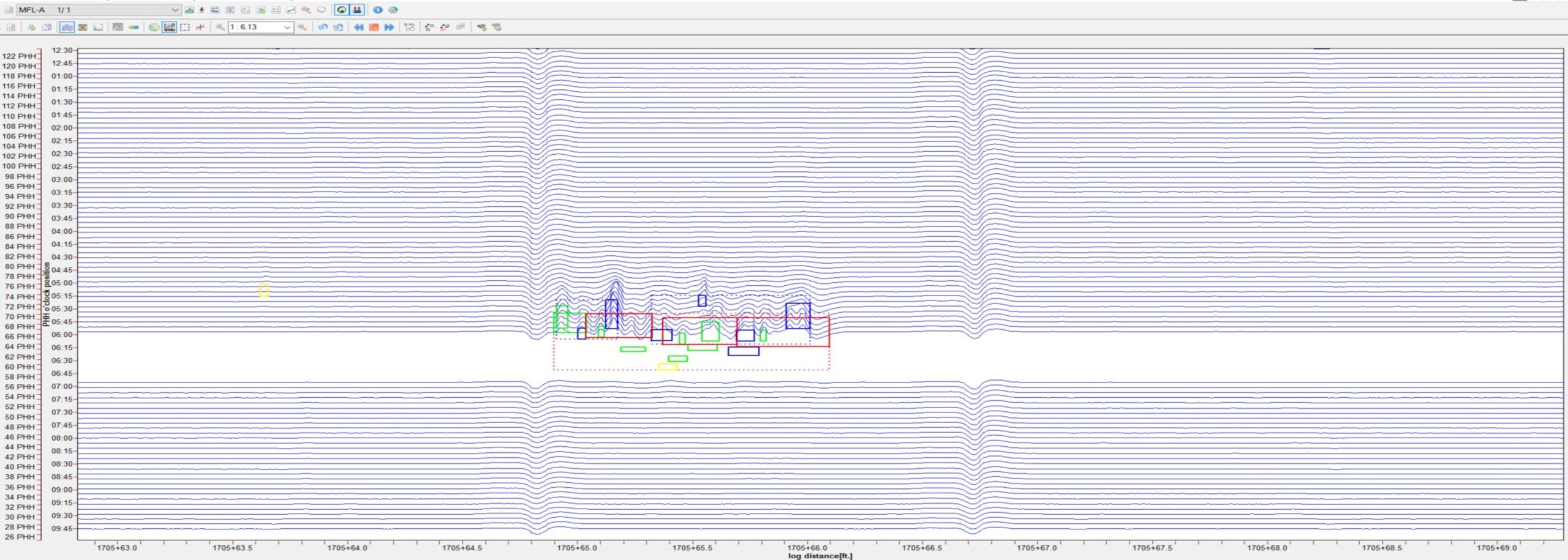

Importance of ILI

In-line Inspection (ILI) remains pivotal in maintaining the safety and integrity of pipelines. By sensing, recording, analyzing, and reporting pipeline conditions, ILI provides valuable insights. However, ensuring its accuracy is crucial for reliable pipeline safety decisions.

Challenges in ILI Correlation

High concentrations of metal loss or complex metal loss shapes can introduce location and sizing errors. Magnetic flux leakage technology and other methods are limited, making accurate correlation challenging.

In-Ditch Verifications and ILI Performance

The 2013 ILI Systems Qualification Standard, API 1163, suggests in-ditch verifications to determine ILI tool performance. However, not all ILI assessments warrant excavations. The API 1163 Second Edition outlines methods to make decisions using alternative data sources.

Kiefner's Approach to ILI Analysis

Kiefner’s comprehensive analysis focuses on responding to ILI-reported anomalies. For low-severity metal loss anomalies, we employ the API 1163 Level 1 performance measure. For high-severity anomalies, we pivot to a Level 3 acceptance criteria, deriving insights from on-field data.

Utilizing Industry Standards for Optimal Results

Kiefner employs standards like API 1163 to provide clients with the expertise required for tool qualification, ensuring confidence in the reported data.

Our mission is to guarantee the most accurate response to ILI-detected anomalies, ensuring the safety and longevity of pipeline systems.