Innovation at Hand: Cutting-Edge Engineering Tools

Empowering Excellence: Explore the arsenal of advanced engineering tools at Kiefner. As a premier Engineering and Technical Service Provider, we leverage cutting-edge instruments and technologies to deliver unparalleled solutions. Our commitment to innovation ensures precision, efficiency, and success in every facet of your engineering projects. Elevate your endeavors with the right tools in the hands of our skilled professionals.

Advancements and Risk Management in Pipeline Integrity, Assessment, and Safety Engineering Critical Assessment of Vintage Girth Welds Presentation Engineering Critical Assessment of Vintage Girth Welds...

Cyclic Fatigue Analysis with Kiefner’s Pipelife Tool Cyclic Fatigue Analysis with Kiefner’s Pipelife Tool Cyclic fatigue is a common concern in the management and maintenance...

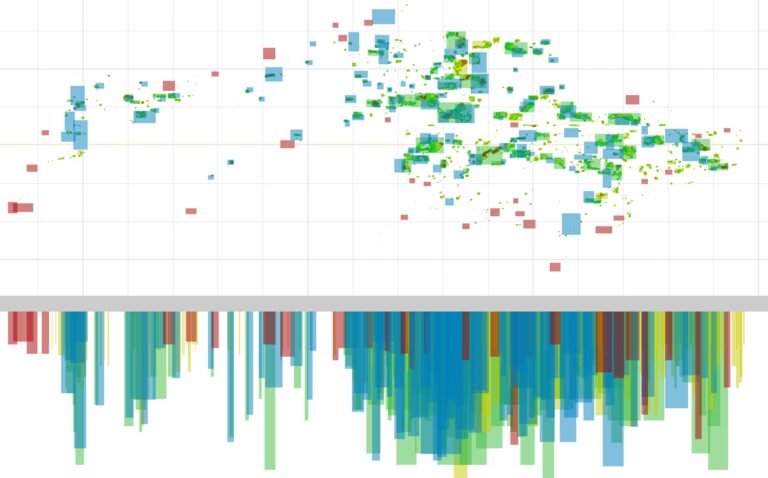

ILI Comparison Tools for Enhanced Pipeline Integrity Harnessing ILI’s Potential In-line Inspection (ILI) is vital for maintaining pipeline safety and integrity. As ILI technologies advance...

KAPA™- B31G Tool for Pipe Assessment Introduction to KAPA™ “KAPA™” stands for “Kiefner and Associates Pipe Assessment.” It is a powerful tool specifically designed to...

Kiefner’s Surface Loading Calculator When subjected to external stresses, the safety and sustainability of pipelines are a primary concern in the industry. Surface loads, especially...

PipeProps™ Confidently verify pipeline material grade for 49 CFR 192 Compliance The Challenge: For pipelines without traceable, verifiable, and complete (TVC) records, 49 CFR § 192.607...

Psqr Plausible Corrosion Profiles Advanced Metal Loss Burst Pressure Analysis with Kiefner’s Psqr Tool The determination of a tool’s burst pressure, especially in the context...

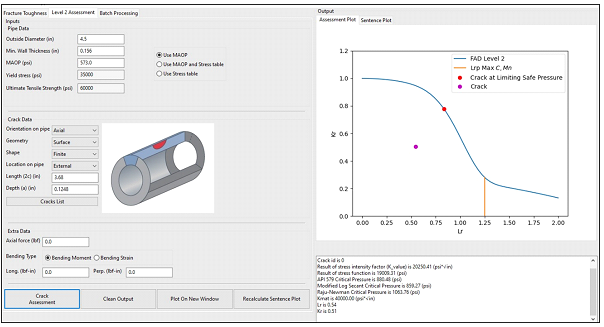

5-7-9™ Crack Assessment Software 5-7-9™ Tool Crack Assessment by Kiefner The integrity of pipelines is fundamental to safe operations. Crack assessment plays a pivotal role...