Precision in Practice: Fitness-for-Service Expertise

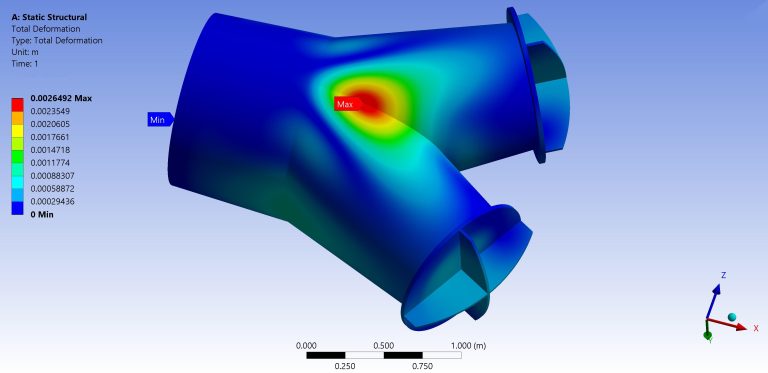

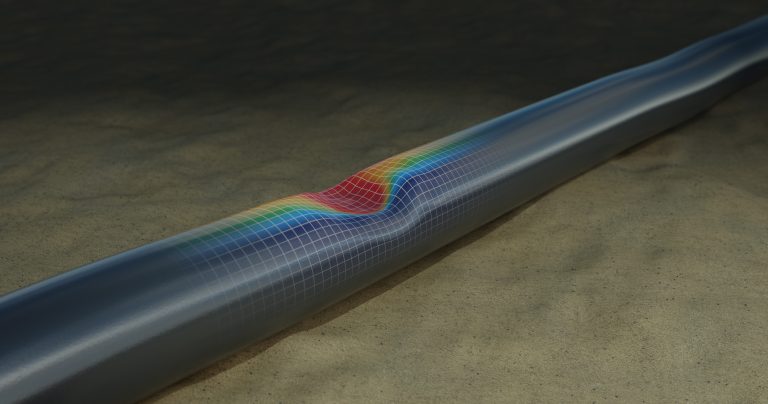

An Engineering Critical Assessment deploys finite element methods to establish acceptance and rejection benchmarks for defects in welds. This approach heavily relies on fracture mechanics, contrasting the conventional good workmanship criteria in welding standards.

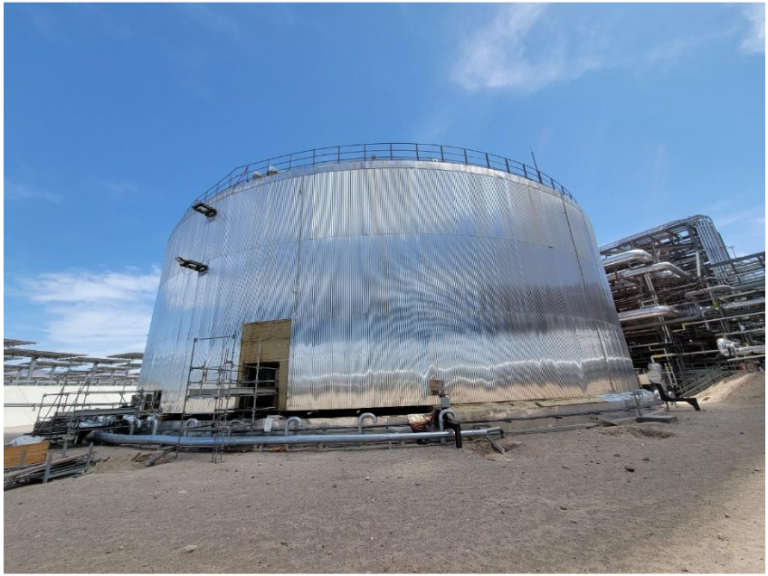

API-653 Hydro Waiver Brochure 1 Reconstruction and major repairs to...

Asset Reliability and Integrity: Prioritizing Equipment Health and Operational Safety...

Code Interpretation and Compliance Introduction Pipelines are crucial arteries of our...

Data Analytics and Machine Learning Data Analytics and Machine Learning...

Engineering Critical Assessment (ECA): Comprehensive Analysis for Safe Pipeline Operations...

Environmental Compliance: Navigating a Greener Path The Modern Environmental Challenge...

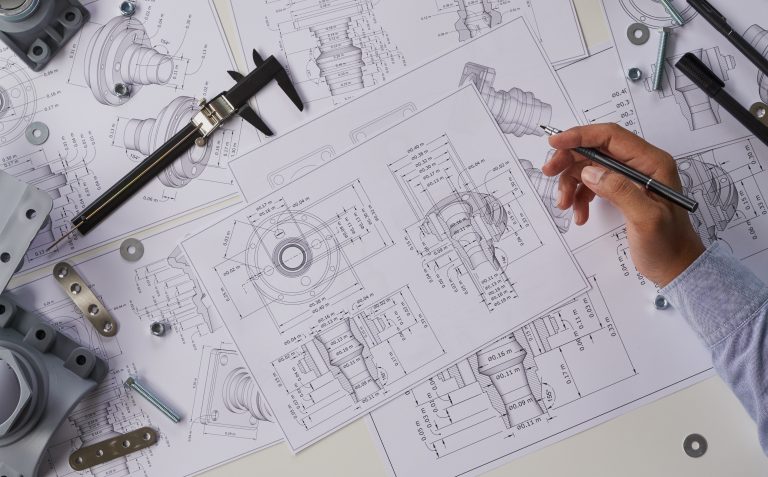

Evaluating Equipment Integrity for Safety and Efficiency Why Fitness-for-Service is...

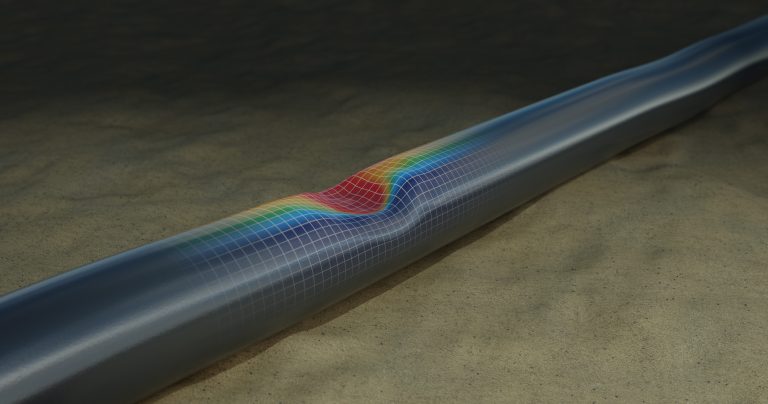

Fatigue and Fracture Mechanics Pipeline Safety Amidst Defects Pipelines can operate...

Geohazard Identification and Management Overview & Importance Understanding and analyzing...

Hydrostatic Test Planning Hydrostatic Test Planning for Natural Gas and...

Process Simulation (HYSYS) Introduction Process simulation is a foundational tool...

Regulatory Support Regulatory Landscape Interstate oil and gas pipelines are...

Remaining Life Assessment (RLA) Introduction The integrity and safety of...

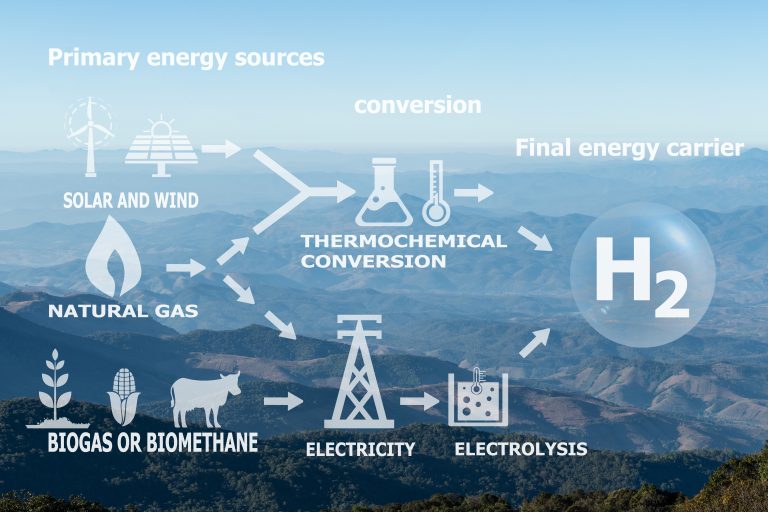

Hydorgen and CO2 Capture Pipelines Solar Parks and Wind Farms...

Risk Assessment in Pipeline Integrity Management Understanding Pipeline Failures To...

Statistical Analysis in Pipeline Integrity Management Significance of Statistical Understanding...

Test Procedures Understanding Testing and Analysis The process of testing...