Hydrostatic Test Planning

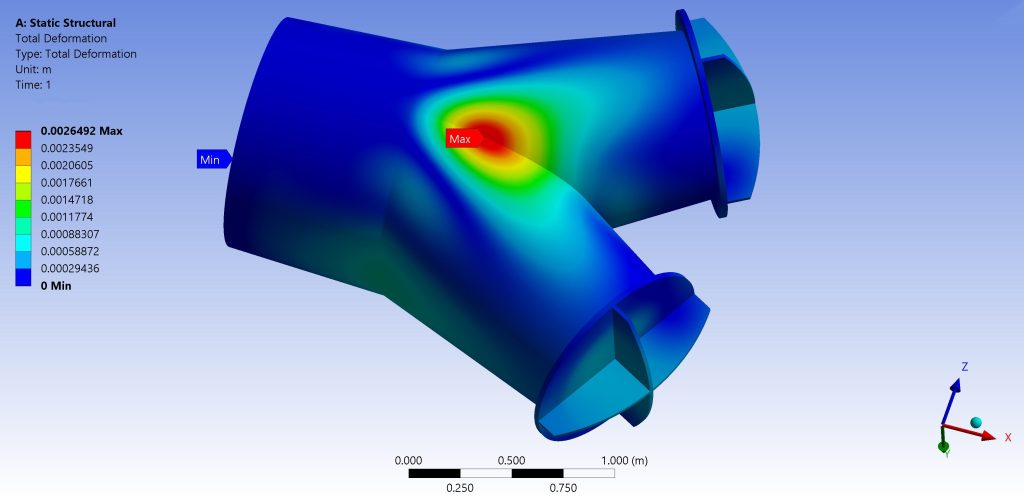

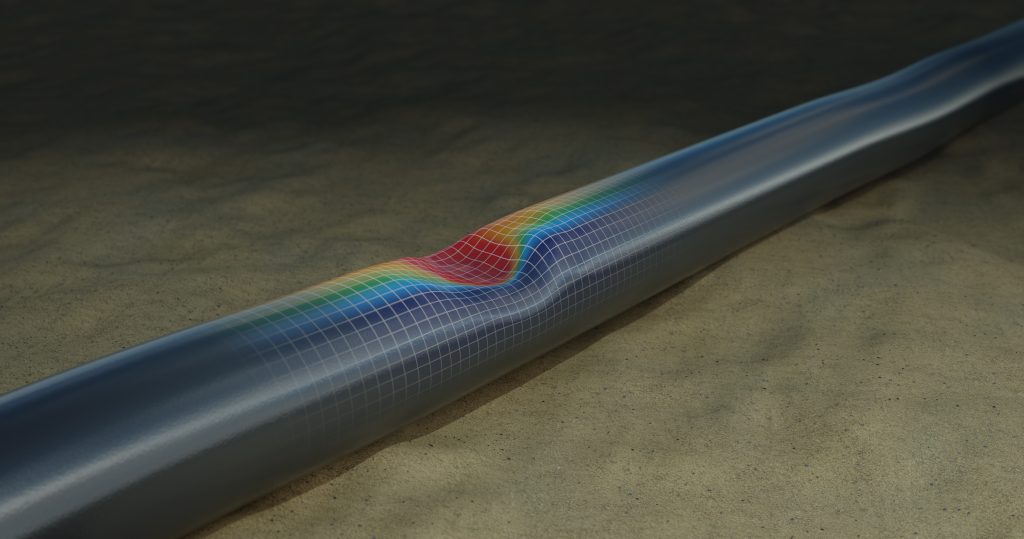

Hydrostatic Test Planning Hydrostatic Test Planning for Natural Gas and Liquid Pipelines Hydrostatic testing is a standard method utilized to verify the structural integrity and strength of natural gas and liquid pipelines. By exerting water pressure inside the pipeline at levels much higher than its operational capacity, any weak spots, leaks, or flaws can be […]

Hydrostatic Test Planning Read More »